Overhaul14: Undeniable Truths of Overhaul 13-18

Ferry Fiasco? It seems schedule delays are not just a warship problem

Introduction

This is the third installment of Undeniable Truths of warship overhaul. Sorry that it is a bit long. I’ve created the list because crew members lack the experience to recognize them until the inevitable collision. The truths in this post are: the crew cannot delay the shipyard (SY), except when they can, the Navy institutionally treats every overhaul like it is the first, best-ever overhaul performance is literally just that: something that is never repeated, and surprise, SYs can’t go faster by hiring more people. Detailed explanations follow.

Undeniable Truth 13: Never delay the shipyard

Never delay the shipyard is a tricky Undeniable Truth because it is almost always true (see UT14 below). Most of the time it is true and the logic is clear. A Navy organization pays huge sums of money to the shipyard to accomplish complicated, difficult, and sometimes risky work that requires experienced engineers and craftsmen. Ship crews that delay the schedule because they haven’t set the plant conditions, established the appropriate work controls, have too many watchstanders at dental appointments (oral health is big in the Navy), have inter-departmental communications issues, or haven’t read the procedures will bring the wrath of the bill payer upon themselves.

Most SYs have a quick response methodology for responding to SF delays: immediately complain to the Commanding Officer. Commanding Officers (CO) then contact the relevant department head and junior officer harangues ensue. This is repeated as necessary until the undeniable truth sinks in for the crew. New people are taught this shortly after reporting aboard the ship. Accustomed to seeing the SY struggle to get out of its own way most of the time, the crew can be truly astonished by how fast shipyard personnel move when they are being delayed by something other than themselves.

Undeniable Truth 14: Sometimes you can delay the shipyard

Undeniable Truth 13: Never Delay the Shipyard is true, but only when stated as “never delay the shipyard without good reason.” The most obvious, but not trivial, justification for delaying the SY is casualty response. No reasonable person expects a procedure or maintenance action to start or continue when someone just fell down a ladder, the ship is flooding, or a person is having chest pains (almost always a SY worker as their demographic skews older).

Less obvious reasons for delaying the SY can be as valid as emergency response, but the bar for validity is high. The delay has to be defensible (in an ironclad, can’t be overruled way) and the SY should be given advanced notice. Even with advanced notice of a delay, don’t expect SY leaders to accept it without resistance. This is why no one below the level of department head should attempt SY delay and they had better inform the CO first. Defensible delay rationales include:

* Safety: actions by the SY that risk sailor injury or may damage ship’s equipment. Examples are more safety rails or barriers for removed deckplates or removing all ladders from a space (that generates ladder padlocks). SY leaders seldom create unsafe conditions on purpose so it is incumbent on the crew to be alert for them and speak up quickly.

Due diligence for safety-related work: processing tagouts, work authorizations, and doing valve lineups are safety-related. Shipyard leaders can complain that the crew needs to assign more personnel to these activities (count on this), but they can’t directly say that the crew isn’t going fast enough. That sounds like they don’t care about safety, which isn’t likely to motivate the CO to intervene. When I was a Reactor Officer on a CVN in overhaul, I told my Chief Petty Officers on more than one occasion not to hurry work control and valve lineups because I wanted the work done right.

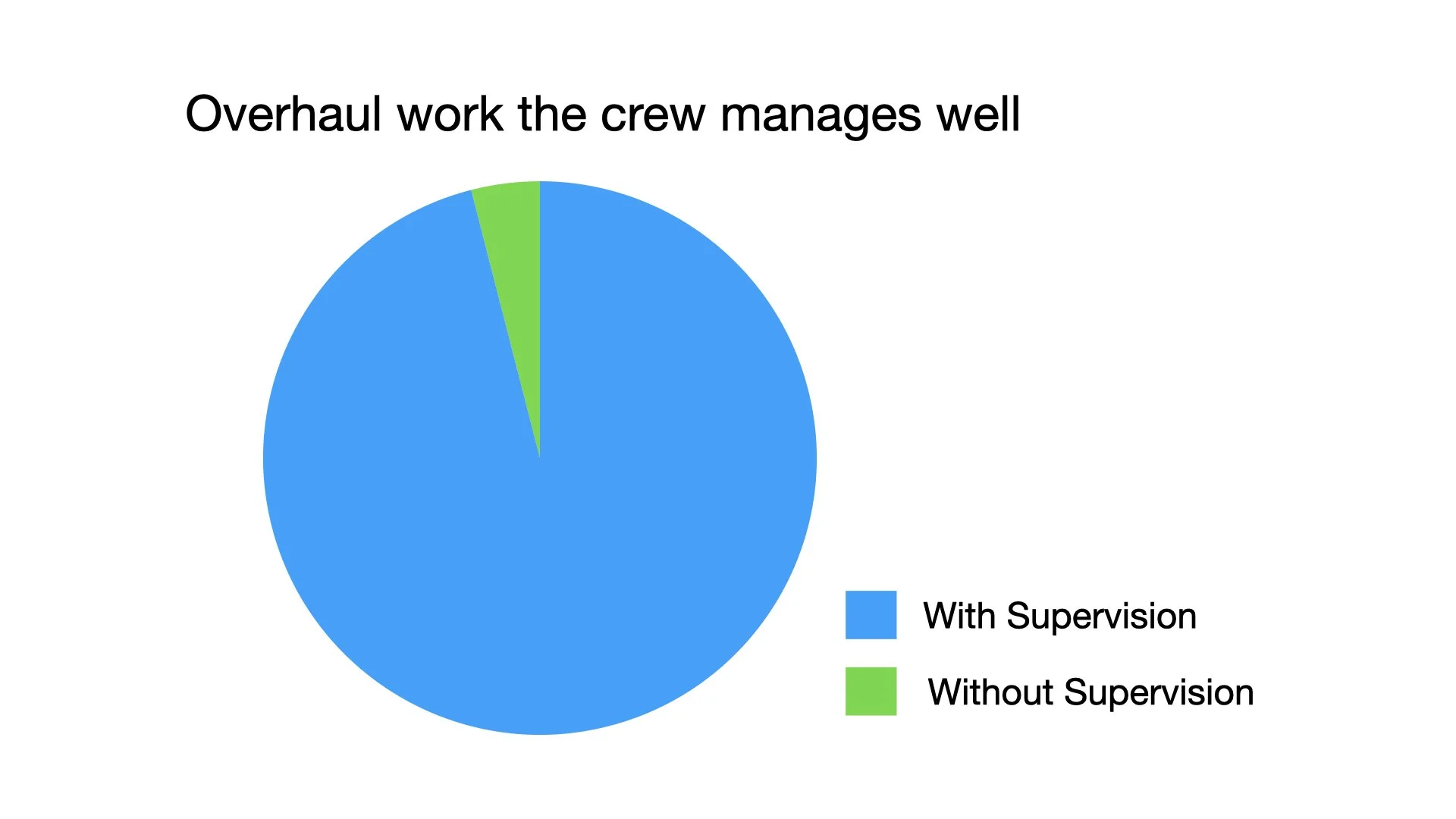

Low numbers of competent experienced personnel-less than 50% of the crew has enough experience to be trusted to accomplish complex tasks on their own (see UT 11). Lack of experience can be partially compensated for with supervision, but recall Undeniable Truth 12, the crew’s most limited resource is supervision. A department head cannot refuse to provide SY support due to manning limitations, but they can limit what they permit in parallel.

Some forms of training-this is tricky because only certain kinds of training-related delays are defensible. If the crew has had a SY procedure for several days, the department head will not be able to justify not having trained on it. Having to do training for crew certification before sea trials is defensible if the SY is informed. While SY leaders may not like the schedule impact of such training, they recognize that sea trials are contingent on passing crew certification. There will be much rejoicing, however.

Cleanliness-this is the trickiest of all reasons to delay the shipyard. First, it is seldom useful to tell the SY that the crew won’t move forward until they clean to Navy standards. They aren’t capable of it. The only thing such a demand will generate is flooding ship spaces with personnel, most of whom will not be cleaning. I never told the SY that they had to clean spaces to my standards, but I did delay some key events, with advanced notice, while the crew did the cleaning.

Defensible rationales for delay are not strictly limited to these cases. Any delay must have a very clear and defensible connection to responsibilities that are exclusive to the crew: safety, work authorization, tagouts, valve lineups, crew resources (mostly), some forms of training, and cleanliness (mostly).

Undeniable Truth 15: Every Navy maintenance period is the first

The work practices, forms, and procedures for ship overhauls differ between maintenance activities, classes of ships, and types of availabilities. Except for aircraft carriers (it may have changed), ship overhaul and support practices are not standardized except for very basic guidelines in the Joint Fleet Maintenance Manual (JFFM). This is no problem when the processes are internal to a SY and have no crew involvement. When the processes are activities that every ship performs, it seems ludicrous. Examples of practices with deep involvement of the crew that are common to every U.S. Navy availability are:

Integration of non-SY maintenance activity work

Work control and tagouts

Project team organization

Managing the test program

Hotwork/Firewatch

Environmental protection

Emergency response (especially for disasters like the USS BONHOMME RICHARD and USS MIAMI fires) Ship security

Radiography

An enthusiastic crew member who wanted to know what to expect in an overhaul and how to set up crew support for it has no reference to consult. Although efforts are underway to provide some standardization for avails, at the time of this writing and since Noah was a shipbuilder, every crew undergoing maintenance learns and implements industrial activity (IA) common overhaul processes on its own. Aircraft carriers may still use Standard Work Practices (SWPs) for avails. SWPs systematized all of the above processes and more. I was the author of the final report and proposed process. It is available upon request.

Undeniable Truth 16: No one knows what NSA stands for

There seems to be no standard expansion of the abbreviation NSA despite its importance. I saw it expanded in different NAVSEA and SY instructions in different ways. Sometimes it was Naval Supervisory Activity. Other times it was Naval Supervising Authority. Sometimes it was a mix of both. Alternate versions are:

Nothing Stupid Allowed-This doesn’t work since my previous writings are testimony to lots of stupid stuff happening in ship overhauls.

No Shenanigans Authorized-This also doesn’t work. People who work in SYs aren’t imaginative enough most of the time to execute shenanigans, but plenty of other parties are.

The NSA is the Commanding Officer of the Navy activity responsible for establishing the ground rules of the overhaul, getting all overhaul participants to follow those rules (harder than you think), and updating the rules when members of an organization have found creative ways to subvert them (shenanigans). There is a lot of under-appreciated creativity in overhauls focused on finding ways not to comply with NSA rules.

Probably the most appropriate, least politically correct expansion for NSA is Naval Scapegoat Assignment.

“Naval,” because it has to be someone in the Navy, normally an active-duty Captain. You can fire a Navy Captain, but not a SY President.

“Scapegoat,” because having an NSA for a maintenance period is all about affixing accountability after things go wrong (i.e., “blame”). Senior Navy leaders and the public don’t seem interested in assigning responsibility for things that go well. That’s usually called “doing your job.”

“Assignment,” because an organization is assigned and expected to establish and enforce overhaul ground rules.

Undeniable Truth 17: Best ever SY performance repeats never

Ship overhauls are cruel examples of “regression to the mean.” After every amazing outcome in any field, performance returns to the mean. If the average delivery from overhaul is late, the next one will also be late unless something substantial changes. The delivery from maintenance might be “really late.” Substantial changes, in contrast to generic statements of concern and firing people, are always expensive and slow. This This a GAO analysis that you can believe. Declarations that “there needs to be a culture change around here” don’t work.

Heroism is real and does happen, but not in SYs and only at the individual level (the french fry station?). Heroism to achieve amazing results rarely results at the organizational level. During overhaul, tens of thousands of activities have to be coordinated, scheduled, engineered (don’t forget “and get fixed,” that’s what trouble desks are for), and de-conflicted (“No, you cannot weld in tanks that have fuel in them!”) to keep moving forward. Overhauls involve lots of conflict resolution. No matter how heroic tank preservation and repair is, it won’t change the overhaul end date.

I was a department head in a Naval Shipyard whose on time performance was consistent, but consistently bad. At project performance briefs, project leaders kept displaying work throughput graphs that compared the throughput of the availability to an unlabeled standard. The comparison was always dreadful. No project came close to the standard. One day I asked a question that seemed reasonable, but clearly no one expected. “What is the source of the standard you’re measuring yourself against?” The answer I received sounded like, “It was [mumble] in 199[mumble] on the USS [mumble] availability.” My next question was, “If that is the standard, what did they do that you aren’t and what are you going to change?” Okay, my two next questions were … The response sounded like “We’ll [mumble, mumble] harder.” I didn’t throw my hard hat, but I forbid the use of that graph from then on. I still don’t know what overhaul throughput is.

Undeniable Truth 18: SYs can't get bigger or go faster

The Fantasy Solutions for Naval Ship Maintenance crowd should have the credibility of flat earthers. They never tire of declaring that SYs need to be bigger so they can do more work faster. That’s their solution for the Navy’s “ships spend too much time in maintenance” problem.

The fantasy collides with reality in two ways, never acknowledged by proponents. The first is that SYs are as big as the Navy can afford. Repairing, modernizing, and refueling Navy ships is expensive, complex, and time consuming. If I haven’t convinced readers of this by now, I’m a worse writer than I thought. Even if SYs could hire lots more people (they can’t because they are doing other things that pay at least as well and most potential hires don’t want to work in a place where they might catch on fire from sparks), train them to be skilled mechanics (possibly, but they’d have to put their phones down long enough to hold a welding rod), and were not limited by the physical space on ships (they are, even on aircraft carriers), the money isn’t available to pay the salaries of more workers. The added workers couldn’t remain proficient because SY workload, unless large amounts of maintenance have been deferred for years, is “spikey.” In the troughs between the spikes, there wouldn’t be enough work for all those extra people. Second, the call for bigger shipyards collides with UT 11: The crew is the weakest link.

Wrap Up

In this third list of undeniable truths of warship overhaul, I focused on:

Undeniable Truth 13: Never delay the shipyard

Undeniable Truth 14: Sometimes you can delay the shipyard

Undeniable Truth 15: Every Navy maintenance period is the first

Undeniable Truth 16: No one knows what NSA stands for

Undeniable Truth 17: Best-ever performance repeats never

Undeniable Truth 18: SYs can't get bigger or go faster

Another set of undeniable truths is coming soon. If you feel that I missed the mark on any of the UTs in this post or the series, please comment.