Overhaul12: Undeniable Truths of Overhaul 1-8

“It is difficult to get a man to understand something, when his salary depends upon his not understanding it!” - Upton Sinclair

Introduction

This post begins a series elucidating the Undeniable Truths (UTs) of ship overhaul. Not all are my invention, but they’re still undeniable. The truths concisely (possibly humorously) restate the main ideas of my previous ship overhaul posts. I wanted to write this post when I began my series on ship overhaul, but I thought that too many required lengthy explanations. I have provided those explanations in previous posts.

If this is the first ship overhaul post you are reading, I encourage you to begin at the beginning of the series. In my eleven posts on Navy ship maintenance, I have described the most important issues associated with ship overhaul.

What happens during overhauls.

How the work is identified and designed.

The role of Class Maintenance Plans.

What overhaul is like for the ship’s crew (short version: painful).

How the crew supports (or doesn’t) the shipyard (SY).

Navy depot maintenance problems from the perspective of the Government Accountability Office (GAO).

The success factors for SY overhaul.

Factors under SY control that lead to overhaul delays.

The “undiscussables” of Navy ship maintenance.

What a lot of people think they know about SY and ship maintenance that just isn’t so.

The Undeniable Truths of Ship Overhaul

Undeniable Truth 1: Lifecycle maintenance isn’t warfighting, but it is a ship’s mission.

Ships don’t exist to provide defense industry jobs. Maybe they do, but saying so in public won’t get your shipbuilding program funded. Ships exist to impress people and put ordnance on target without getting sunk. As noted during hearings on the survivability of the Littoral Combat Ship, members of Congress are picky about the whole “return to port” thing. Lots and lots of maintenance and modernization are required for a ship to be as capable after thirty years of sitting in saltwater as when it was commissioned.

To perform their missions, ships and their crews need supplies, ammunition, and spare parts (“kill chain” stuff). So too with lifecycle maintenance. You just can’t load it with a working party. If you don’t repair and modernize warships frequently, their appearance alone might demonstrate resolve. Showing resolve is a big thing in spend-more-on-defense reports like Commission on the National Defense Strategy. Poorly maintained warships might reassure allies, scare bad guys (probably not the ones firing missiles in the desert from pickup trucks), and keep sea lanes open if they can still get underway. Without maintenance and modernization, the ability of warships to go where national maritime strategy dictates, blow things up when they get there, and stay afloat after being attacked degrades.

While it is understandable for crews to prefer being at sea deterring bad actors, sailors must accept that maintenance and modernization, sometimes in the SY, is not just “part of” a ship’s mission. It is the mission when it’s happening. It is a mission because, unlike ammunition and supplies, you can’t load and store maintenance with a working party. Maintenance requires the total engagement and support of the crew just as much as firing weapons.

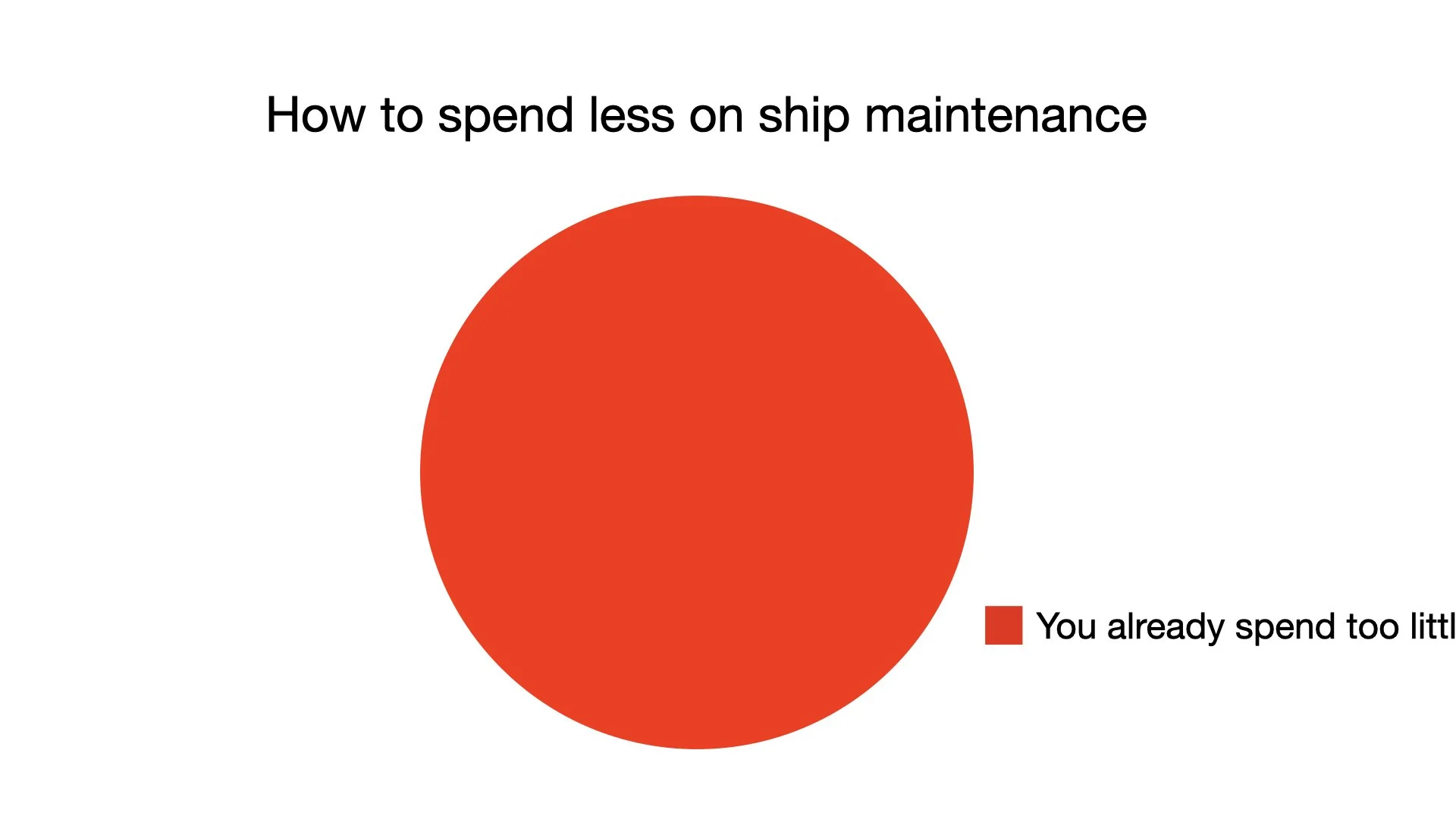

Junior officers will continue to write articles for Proceedings of the U.S. Naval Institute claiming that junior officers would be better employed sailing into harm’s way, swords strapped to their sides, a button push from launching ordnance. The lifecycle maintenance that the U.S. Navy can afford depends on most of the crew remaining aboard the ship, doing some work, and supporting the maintenance activities. Actually funding it is another matter.

Undeniable Truth 2: The ship’s crew can’t speed up an overhaul; they can only make it late.

The shipyard (SY) manages the schedule, the resources (people and material), and new work. The crew lacks any influence over them. The crew helps the shipyard best when they set plant conditions and stay out of the way.

The crew can delay the overhaul end date by not allowing the shipyard to work at its most efficient pace, not reporting material problems (causing them to be discovered late), not finishing their work on time, and poorly executing the work that only they can do (work isolation and operating equipment).

Undeniable Truth 3. Blaming doesn’t accelerate an overhaul.

Sometimes referred to as the third law of thermodynamics, finger-pointing (blaming) is distinct from accountability. Holding people accountable when they clearly did the wrong thing is essential for maintaining high standards. Finger pointing is different than owning up to mistakes and correcting them. Some SY problems don’t have a clearly responsible individual (being behind schedule, new work, losing material, etc.). Others have a responsible party, but are just part of overhaul (damaging installed equipment, testing failures). When senior members of the ship’s crew focus more on blaming than recognizing, fixing, and moving on from problems, it can cause two problems.

First, a blame-focused crew isn’t managing their work (see UT2). Second, it can keep SY managers so busy responding to accusations that they lose their focus on managing their work. Overhauls are hard. The work is complex. Mistakes happen. The best approach for responding to mistakes is first to focus on keeping them small. Next, don’t kill anyone, understand what happened and fix them (if possible), and move on.

Undeniable Truth 4. Accountability in ship repair is limited.

I write about this in my posts on ship maintenance realities, but it bears repeating. First, the SY responses for poor work quality, planning errors, and delays don’t look like accountability as practiced in the military: firing miscreants, demotion, court-martial, etc. In the SY, accountability takes the form of people getting reassigned to other work, removed from their positions, and re-trained. Except in the most egregious cases like falsifying records, these consequences make more sense than firing or demoting people. It works the same way in the Navy. Taking someone to Captain’s Mast is not the first resort for correcting performance problems. Second, if you are complaining that people who made errors aren’t being punished the way you want, see UT3.

Undeniable Truth 5. Ship’s force depends on cooperation and assistance from the SY to accomplish their work.

Ship’s force needs to “cooperate to graduate” from the SY. This goes beyond the shipyard completing the work assigned in the Availability Work Package. Help needed from the shipyard includes: temporary services, industrial supplies, and de-conflicting shipyard work to make SF work possible.

SY support for the ship is government by contracts, union agreements, regulations, and goodwill. If the crew goes into blame mode and complains constantly about the shipyard (see UT3), it makes SY workers defensive and less inclined to respond favorably to requests for assistance that aren’t required.

Undeniable Truth 6. The critical path is never the critical path.

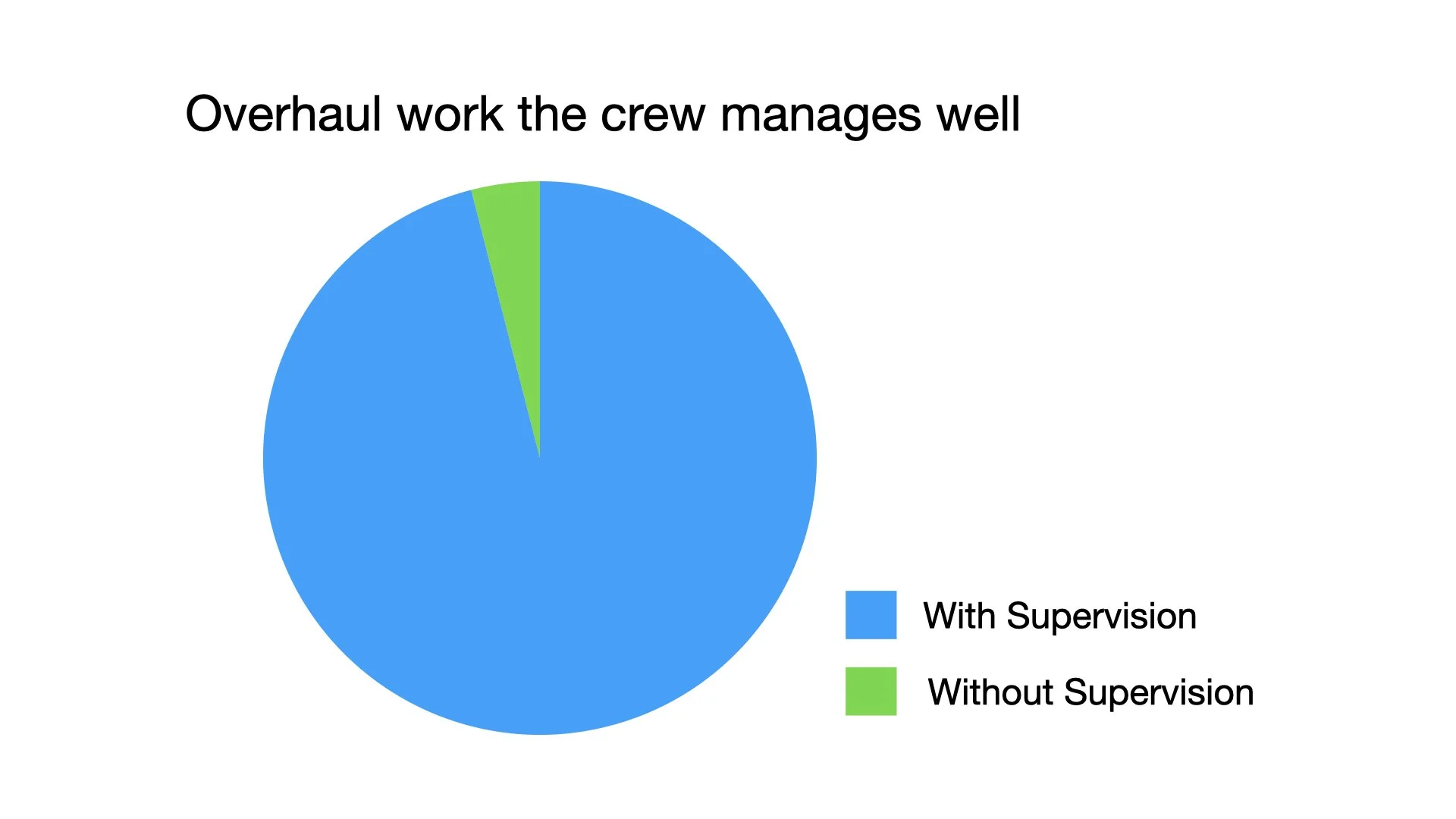

“Critical path” is a scheduling term that refers to the duration of work with the greatest influence on the end date of the overhaul. SYs perform the analysis before every overhaul, but what the analysis predicts will be the critical path seldom actually is. There are two reasons. First, the SY prepares extensively to reduce foreseeable delays to the critical path: training, job planning, special tooling, advanced material procurement, experienced personnel, supervision, dedicated technical support, and specialized work routines. These measures work well for capturing and defeating foreseeable problems as well as facilitating rapid responses to the unexpected. More importantly, new work is frequently discovered or there are unexpected problems with other work that make them the critical path. An overhaul is like a box of chocolates …

Undeniable Truth 7: Overhaul end dates cannot be imposed by outside agencies (or sometimes even the shipyard).

When third parties dictate the overhaul end date or won’t accept the shipyard’s proposed completion date, it is a near guarantee that the overhaul will finish late. It is one thing for a third party to challenge the SY’s schedule, assumptions, and strategies for accomplishing particular jobs. It is a completely different matter to refuse to accept the SY’s schedule estimate for non-technical reasons or insufficient financial resources to pay for a longer overhaul.

The practice of dictating overhaul end dates is curious. Navy leaders place ships in a SY because they have confidence that their leaders and workers have the capability to plan and execute the work to very high standards (most of the time, see UT 4). The mental gymnastics necessary to reject the recommendations of people with decades of experience doing some of the hardest work on the planet (i.e., repairing and testing warships) could be an Olympic event.

Undeniable Truth 8: It’s always the shipyard’s fault.

Whenever a ship delivers late from overhaul, Navy headquarters activities and staffs always blame the shipyard. No one outside the shipyard cares about the new work discovered, the inadequacy of the planning process, crew performance or leadership issues, or that the end date was dictated for non-technical reasons (UT 7).

There is a certain logic to blame the SY strategy. First, you don’t have to ask embarrassing questions of non-SY organizations like “How could you not know the material condition of the ship?” Second, you don’t have to know anything about the technical or performance issues that caused the delay. Third, one can always argue that the shipyard could have done more to identify the work, do the work better, train and support the crew, etc. This isn’t always true because senior leaders of the crew can be blockheads resistant to help.

People on Navy operational staffs or in the Pentagon don’t know or care about the details of overhauls: the complexity of the work, the stability of new designs, whether Government Furnished Material/Information (GFM, GFI) was provided on time, dictated end dates, and ship’s force support of the shipyard. They aren’t bad people (most of them). They just care more about things that are more pressing such as having to redo the schedules of multiple ships and training organizations to accommodate the later end date. As a friend of mine said, “Frustration leads to anger and anger seeks a target.” SYs are an easy target. You could be shooting arrows facing away from the shipyard and still hit it.

Wrap Up

This post was the first installment of Undeniable Truths of Overhaul. In ship lifecycle management, there are no solutions, only tradeoffs. Tradeoffs are impossible, however, if you refuse to acknowledge that they exist. I have yet to read a LinkedIn post, a GAO report, or RAND Corp study (unless I was an uncredited contributing author) that acknowledged the undeniable truths about ship overhaul. Like trying to defy the laws of physics, ignoring the undeniable truths of ship overhaul opens an industrial-size drum of pain and suffering for the crew and organizations that have to bear the consequences. The Undeniable Truths of Overhaul will continue in my next post because I’m having too much fun to stop.